Automated logistics process for FOSBs/FOUPs – from packaging to shipment

cts at the SEMICON Southeast Asia 2025

Automated logistics process for FOSBs/FOUPs – from packaging to shipment

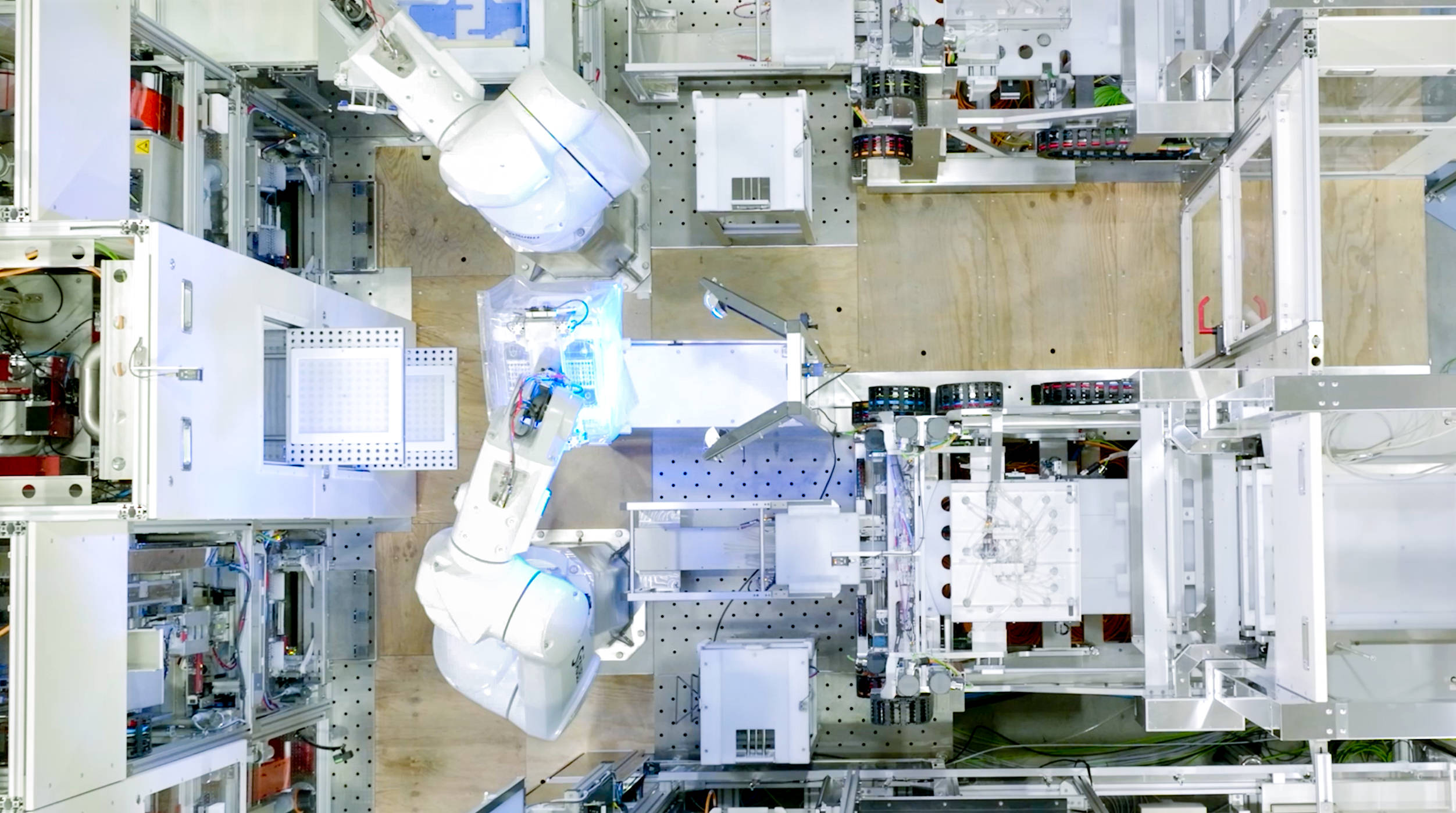

Burgkirchen/Alz (Germany), April 24, 2025 +++ At this year's SEMICON Southeast Asia in Singapore, the cts group is presenting its solutions for the “Smart Semiconductor Fabrication”– high-precision, cleanroom-compatible automation that optimizes wafer production through stable, efficient processes. One highlight of the trade fair appearance is the Auto Bagging Tool (ABT), the most compact, fully automated packaging system for FOSBs and FOUPs on the market. With integrated quality controls, such as 100% leak testing, the solution significantly reduces the number of returns and the associated effort and costs. And, with a direct connection to the likewise presented modular Smart Warehouse lines that maximize storage capacity for electronic components and ensure a seamless material flow, it enables the automation of the entire FOSBs/FOUPs logistics process – from packaging to shipping.

The full-service provider for automation that drives efficiency, safety, and sustainability cts and its solutions for the Smart Semiconductor Fabrication can be found at booth B1716 hall D from May 20-22, 2025.

Semiconductor fabrication is becoming increasingly important in view of the growth of future technologies such as IoT, AI and edge computing. As a result, production is becoming more demanding and high requirements are being placed on the quality, efficiency and speed of processes. Areas that are still very time-consuming, labor-intensive and error-prone include loading, unloading, storing, packaging and transportation of the delicate wafers. The reason for this is a lack of automation.

cts, a full-service provider for customized automation and digitalization based in Germany, will be showcasing its automation solutions at SEMICON Southeast Asia, which address precisely these shortcomings in order to make semiconductor production more efficient.

ABT - fully automatic, fast packaging of FOSBs/FOUPs with quality control

“Our ABT provides a fully automated packaging process for Front-Opening Shipping Boxes (FOSBs) and Front-Opening Universal Pods (FOUPs) starting from a unit size of just 6m x 5m”, explains Alfred Pammer, VP Sales & Marketing.

The system uses code identification to ensure that each FOSB & FOUP is correctly assigned to the appropriate wafers, and an integrated labeling system to assure that the packaging meets the highest standards and all information is properly documented. Unique automated controls can also be incorporated. The 100% leak test, for example, makes sure that only securely sealed FOSBs/FOUPs are shipped, which immensely reduces the complaint rate and therefore costs. And the 100% label inspection checks the legibility of machine codes (barcode, QR/DMC) and the correct printing of all characters, frames, etc.

Overall, this complete automation eliminates manual intervention during packaging, increasing packaging quality, reducing the error rate and speeding up packaging considerably. Thanks to its SECS/GEM compatibility, the ABT system can also be seamlessly integrated into existing production lines without the need for extensive customization. It is ideal for manufacturers who value safety, efficiency and cleanroom standards.

Smart Warehouse – scalable storage for modern semiconductor production

The Smart Warehouse family includes two scalable solutions designed for semiconductor manufacturing environments: The Smart Warehouse / Mini is a compact, cleanroom-compatible system for the automated storage and retrieval of sensitive materials such as FOSBs, FOUPs, and wafer boxes. It supports real-time tracking, fast in-/outbound handling, and helps optimize limited cleanroom space near process tools. The Smart Warehouse / Big supports upstream and downstream logistics – for example, storing packaging materials, carriers, process containers and even packed FOSBs/FOUPs after they leave the cleanroom. It offers high-capacity, fully automated storage outside the cleanroom and enables seamless material flow between fab, backend, and logistics zones.

“The Smart Warehouses require up to 40% less space than other solutions, allowing more storage without additional storage areas”, says Alfred Pammer. “Moreover, their high degree of automation in storage and delivery not only means fewer error-prone manual steps, but process stability and a precise, fast material supply from the warehouse to the SMT line or ABT. Seamless integration with AMRs from Omron, Agilox, MiR and other manufacturers additionally contributes to this efficient material transfer.”

The intelligent systems also enable real-time tracking from warehouse to production line and back. This allows supply chain data and factory operations to be better synchronized, which in turn supports predictive inventory management that avoids overstocking, material shortages and delays.

One of the biggest advantages of the cts storage solution, however, is that it is truly customized automation. Thanks to their modular design, the Smart Warehouses are fully scalable in terms of capacity and functionality. This means that the initial investment can be kept low with a “small” system that can easily be expanded to meet demand fluctuations and higher production requirements, if necessary.

Apollu – automated loading and unloading during polishing and lapping processes

The Apollu tool fully automates manual loading and unloading in the highly sensitive polishing and lapping processes of wafers. Thanks to the integrated camera-based positioning system, wafers are placed and removed automatically with high precision and faster than with any other system on the market, as no sensor-based indexing, adjustment or probing is required. This ensures maximum efficiency and process reliability. The solution supports wafer sizes from 150 to 300 mm, regardless of the machine manufacturer, and also complies with ISO 7 standards for clean room operation.

In addition, the system requires only a short set-up time, allowing it to be flexibly adapted to changing production requirements.

For more information about the Smart Semiconductor Fabrication solutions visit cts from 20 -22 May 2025 at SEMICON Southeast Asia at booth B1716 hall D or www.group-cts.de/en/smart-semicon-fab.

About cts

The cts Group is a full-service provider of customized automation and digitalization solutions for various sectors, from the pharmaceutical and chemical to the electronics and food industries. The service portfolio is divided into four main areas: Smart Processes provides safe and efficient planning, control, implementation and continuous optimization of industrial process equipment. With Smart Manufacturing, cts offers specialized solutions for the automation and improvement of industrial production and intralogistics processes, for instance through the integration of robotics and intelligent warehousing. Smart Data includes services for the digital transformation of production processes by customizing software and interconnecting IT and OT systems for predictive maintenance, real-time insights and automated workflows. And Smart Energy Technology focuses on planning, implementing and modernizing energy systems and energy infrastructure, for example by incorporating renewable energies. The cts Group operates on a vendor-neutral basis and offers all services from a single source: initial consultation, implementation, optimization and beyond. Founded in 2006, the company now maintains numerous locations in Europe, Asia and North America as well as a worldwide partner network. The head office is located in Germany.

www.group-cts.de/en

Press Contact

Micha L. Harris

Senior PR Consultant

Carta GmbH

Iggelheimer Str. 26

67346 Speyer

Germany

T: +49 (0) 6232 100 111 20

E:

About Carta GmbH

Founded in 2001, the PR agency Carta is one of the leading PR service providers in the Rhine-Neckar region and Rhineland-Palatinate. It covers the entire spectrum of public relations. This includes, in particular, press relations, international trade press relations, media relations, and acceptance, project, and citizen communication (public affairs). With a dedicated team of 25 experts, Carta supports large and medium-sized companies, institutions, and organizations in developing communication strategies, creating targeted content for internal and external communication, and distributing this content globally across multiple channels. In addition, Carta offers international companies special support in successfully entering the German market.

Further information is available at: www.carta.eu