Romaco at PACK EXPO in Las Vegas, USA - Recyclable blister packs

Romaco at PACK EXPO in Las Vegas, USA

Recyclable blister packs

Karlsruhe/Germany, 2025-07-30 +++ At this year’s PACK EXPO in Las Vegas, Romaco will demonstrate how its Noack N 760 blister packaging machine manufactures blister packs from PET mono-material. The PVC-free PET/PET blisters reduce the carbon footprint of the end product. What’s more, they offer equivalent barrier properties to PVC/aluminium blisters when used as an alternative for products currently packaged in this way.

The field of pharmaceutical packaging is one of many in which sustainability is rising to the top of the agenda. Around the world, packaging and film manufacturers are carrying out research into alternatives to the standard PVC and aluminium blister packaging commonly used across the globe. These are made of laminate comprising several layers of plastic and aluminium – a complex mix of materials that cannot be sorted or recycled after use and which is therefore incompatible with the circular economy. Blister packs with a forming and lidding foil of PET (polyethylene terephthalate) offer a more sustainable solution. This mono-material is approved for use in the primary packaging of pharmaceuticals and nutraceuticals, and can also be recycled.

At the PACK EXPO, Romaco will demonstrate the machinability of the innovative One-Material Blister foil (OMB™) from Liveo Research on its Noack N 760 blister packaging machine. The PET One-Material Blister foil has been certified recyclable by the TCEP (Tray Circularity Evaluation Platform). Moreover, when used for products currently packaged in PVC/aluminium blisters, the PET/PET blisters boast equivalent barrier properties to their PVC/aluminium counterparts, facilitating the switch to this eco-friendlier alternative. And when it comes to pushing the tablets through the lidding foil, the PET/PET blisters are entirely as user-friendly as the conventional blister packs. Additionally, the significantly lower weight of the PET/PET blisters also puts them ahead environmentally.

In four-lane operation, the Noack N 760 platen sealing machine achieves a maximum output of 150 sustainable PET/PET blisters per minute. An international pharmaceutical group is already marketing painkillers in primary packaging made of PET OMB™ from Liveo Research.

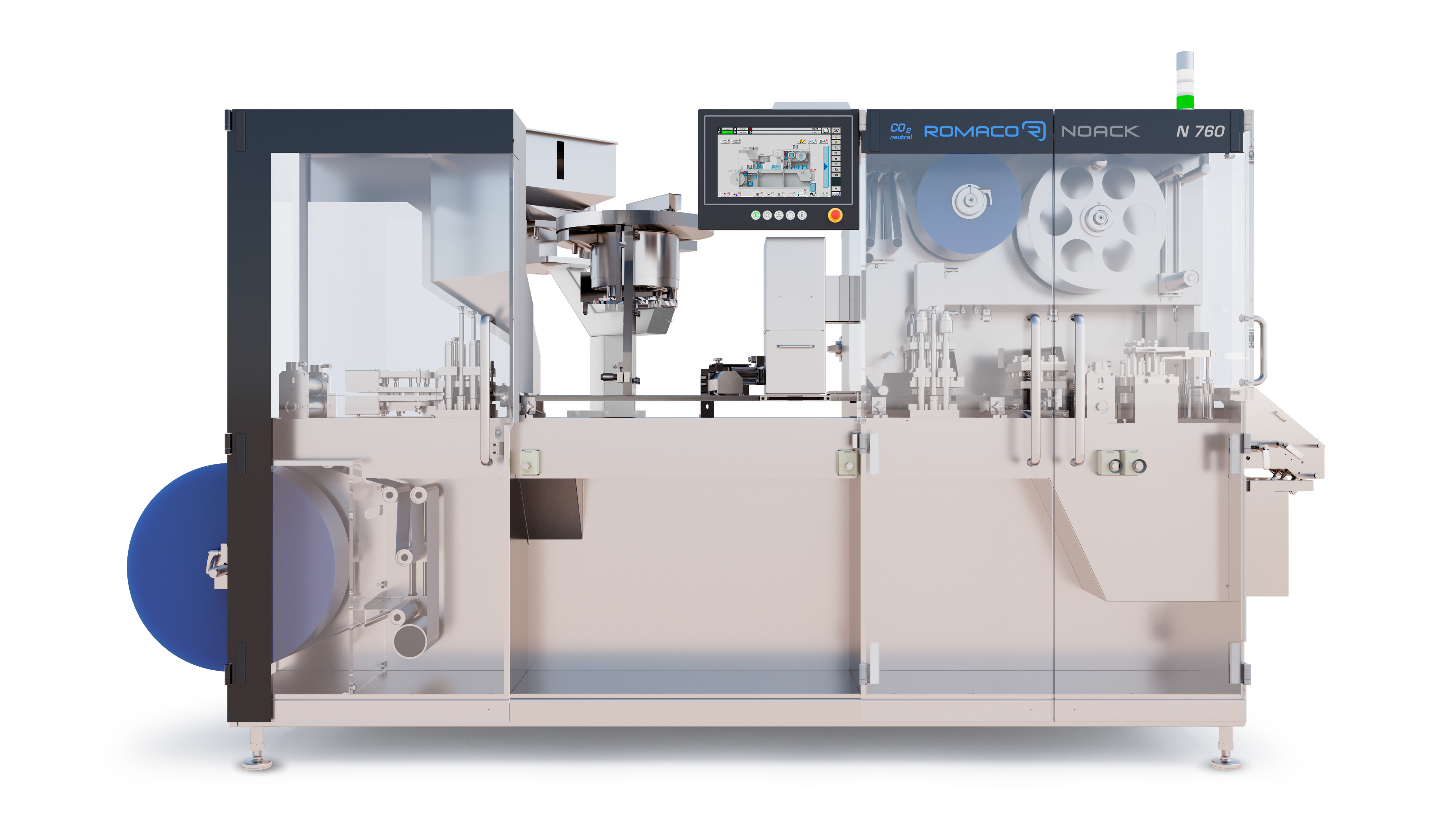

N 760 blister packaging machine by Romaco Noack

The N 760 by Romaco Noack is an intermittent motion blister packaging machine in balcony design for universal use. It is perfect for packaging a very broad range of products from solid dosage forms, ampoules and medical devices to semi-solids. Blisters with a maximum forming area of 155 x 138 mm and a maximum forming depth of 25 mm can be produced in this way. Product changes can be carried out quickly and easily, because only a very few compact and lightweight format parts need to be replaced and all parameters are electronically stored. The N 760 has an exceptionally space-saving layout and is easy to operate, fulfilling all of the requirements of the contract packaging sector, which needs to respond quickly and flexibly at any time to dynamic market situations. With a maximum output of up to 200 blisters per minute, the technology is mainly deployed to produce smaller batch sizes in the low to medium speed segment. The product feeding unit is available in different configurations and is either manual or fully automatic, for example when used with high-tech systems for demanding products or multi-dose blisters. The electrical cabinet can be swung out, meaning the N 760 is readily accessible for maintenance work. Furthermore, the extremely short foil web from the forming station to the die-cutter restricts the amount of waste while running in and retooling the machine to a minimum. Users have the option of connecting the N 760 blister packaging machine to a cartoner and a case packer.

One stop solutions by Romaco and Truking

In addition to its Noack N 760 blister packaging machine, Romaco will be demonstrating the TPR 25 Pilot mobile tablet coater from Romaco Tecpharm for batch sizes from 5 to 100%, or 1 to 25 kg. It will also be presenting the CF 180 capsule filler from Truking, which achieves a maximum output of 180,000 capsules per hour.

On show from September 29 to October 1, 2025 at PACK EXPO in Las Vegas, Healthcare Packaging Pavilion, North Hall, Booth N-5404

For more information on Romaco, visit our website and social media channels: www.romaco.com – Showroom – LinkedIn – YouTube

Romaco Group

Romaco is a leading international supplier of processing and packaging equipment specializing in engineering technologies for pharmaceutical products. The Group provides individual machines, lines and turnkey solutions for manufacturing, filling and packing powders, granulates, pellets, tablets, capsules, syringes, liquids and medical devices. The company also serves the food and chemical industries. Through its various technologies, Romaco is committed to sustainable production and to systematically reducing CO2 emissions.

The Romaco Group has its headquarters in Karlsruhe (Germany) and is part of Truking Technology, a globally operating high-tech enterprise based in Changsha (China). Truking’s core competency is handling and filling pharmaceutical liquids.

Romaco operates from six production sites worldwide, with a broad portfolio comprised of seven established product brands. Noack and Siebler (Karlsruhe, Germany) supply blister, heat-sealing and rigid tube filling machines. Macofar (Bologna, Italy) markets technologies for filling sterile and non-sterile powders and liquids. Promatic (also Bologna, Italy) specializes in cartoners, track & trace systems and case packers. Kilian (Cologne, Germany) is a leading manufacturer of tablet presses. Innojet (Steinen, Germany) is in the business of granulating and coating fine solid particles. Tecpharm (Barcelona, Spain) offers tablet coating technologies.

More than 930 highly skilled and committed Romaco employees are dedicated to the development of future product technologies and to the continuous implementation of internal improvement processes. The Romaco Group’s multi-brand system solutions are sold worldwide through ten Sales & Service Centers and a dense network of local agent organizations. Over 12,000 installations delivered by Romaco are currently in use in more than 180 different countries.

Press contact

Micha L. Harris

Senior PR Consultant

Carta GmbH

Iggelheimer Str. 26

67346 Speyer

Germany

T +49 (0)6232 100 111 20

E

Company contact

Susanne Silva

Market Communications

Romaco Group

Am Heegwald 11

76227 Karlsruhe

Germany

T +49 (0)721 4804 0

E

About Carta GmbH

Founded in 2001, the PR agency Carta is one of the leading PR service providers in the Rhine-Neckar region and Rhineland-Palatinate. It covers the entire spectrum of public relations. This includes, in particular, press relations, international trade press relations, media relations, and acceptance, project, and citizen communication (public affairs). With a dedicated team of 25 experts, Carta supports large and medium-sized companies, institutions, and organizations in developing communication strategies, creating targeted content for internal and external communication, and distributing this content globally across multiple channels. In addition, Carta offers international companies special support in successfully entering the German market.

Further information is available at: www.carta.eu